Mixed Flowing Gas (MFG) is a type of laboratory environmental testing for products, particularly electronics, to evaluate resistance to corrosion due to gases in the atmosphere. Mixed Flowing Gas (MFG) test is a laboratory test in which the temperature, relative humidity, concentration of gaseous pollutants, and other critical variables are carefully defined, monitored and controlled.

The purpose of this test is to simulate corrosion phenomenon due to atmospheric exposure. The electronic product is exposed to gases such as chlorine, hydrogen sulfide, nitrogen dioxide, and sulfur dioxide at levels in the parts per billion range, in a controlled environmental chamber.

- ASTM B827-97

- ASTM B845-97

- ASTM B810-01a

- ASTM B825-97

- ASTM B826-97

- ASTM B808-97

- EIA 364, Test Procedure 65A

- IEC 60068-2-60

- IEC 512-11-7

Fully automated control software and test management.

Process Reactor Size – 36″ x 36″ x 16″

Temp / Humidity Range – 30 – 50C temp, 40 – 80% RH

Pollutant Gas Range –

- H2S: 20 – 2076 ppb

- SO2: 20 – 1250 ppb

- NO2: 20 – 2888 ppb

- Cl2: 10 – 450 ppb

Benefits of ATC Test Lab

A2LA Accredited Test Lab

Many manufacturers want to avoid hiring a certified professional to conduct their sophisticated testing. By contracting ATC Test Lab you can avoid hiring and training costly specialized employees and equipment to conduct an array of tests.

Our experienced laboratory technicians technicians understand the nature of each test, including ASTM B117. They are able to quickly detect product failure or unusual corrosion.

Specialized Testing Equipment and Chambers

ATC has new state of the art equipment to perform the most advanced testing. We have over 1200 Cubic Feet of testing space available, and the largest testing chambers in the world.

By contracting us, you can save money on new costly equipment, maintenance, and down time. You can size and scale your tests based on your level of production.

Receive Photographs and Updates

The best way to monitor your products during the testing process is though digital photography. ATC Test Lab offers high resolution photos at your requested intervals. The use of photographs can help you save money if you need to stop the test early due to product failure or unusual corrosion.

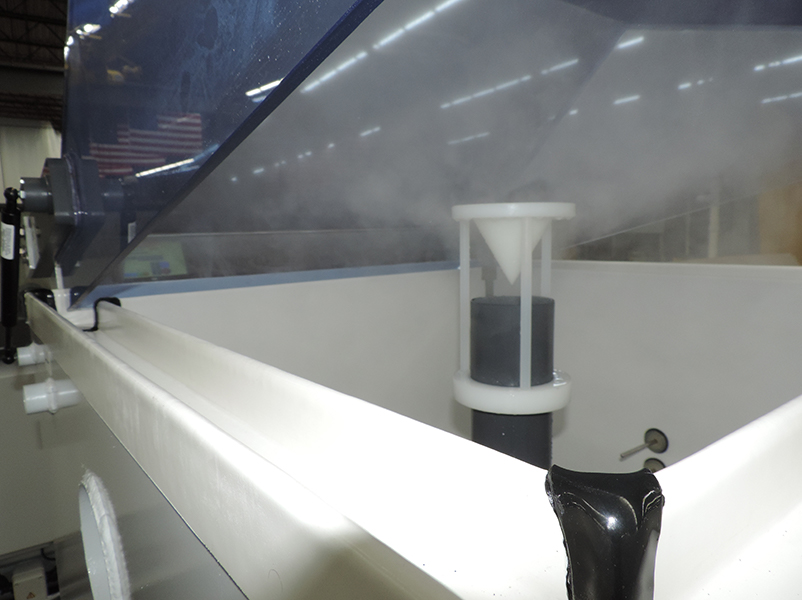

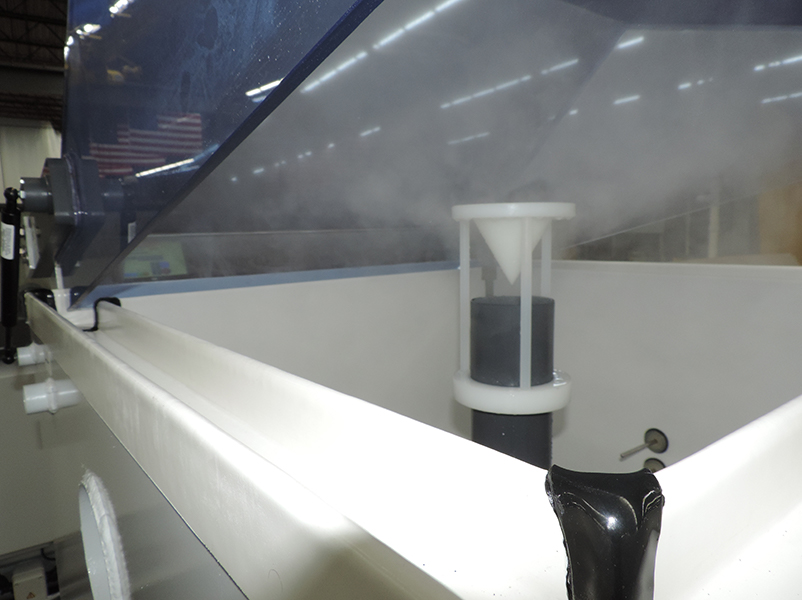

ASTM B117 Salt Spray Testing being conducted at ATC Test Lab

Mixed Flowing Gas

Salt Fog Testing Chamber

ATC Test Lab is the Largest Contract Corrosion Test Lab.

- We have over 1200 cubic feet of testing space available.

- Large testing chambers

- Our lab has state of the art equipment to perform the most advanced testing.

- Experienced laboratory technicians conducting your tests.