GMW 3172 is another common standard that we run at ATC Test Lab. Along with other corrosion tests, GMW 3172 is used to evaluate the corrosive properties associated with manufactured components. What make this specification unique is that it is specifically written for the testing of Electrical/Electronic (E/E) components. According to GM, this standard is for any device that can connect to or is part of the vehicles electrical system, while considering the mounting location of such components. The other unique property about this specification is that it allows the user to have the option of having power supplied to the device. GM give 3 different categories of Operating Types and depending on which category you would like the component to fall under, will help determine which test is better suited for your component. The testing categories associate this specification include Mechanical, Electrical, Climatic, and Enclosure. Within each category are a large variety of test methods that can be used to evaluate your component. However, here at ATC, we specialize in the area of Climatic Testing. Two common test that we see here are in sections 9.4.7 and 9.4.8. GMW 3172 sec. 9.4.7 is referred to as a Salt Mist Test. The procedure is split into 2 parts, with the first part occurring with the component powered ON, and second proceeding with the power OFF. Part 1 is performed by misting 5% salt solution over the parts using a collection rate of 0.25-0.5 mL/hr. This portion is done for a period of 2 hours. The following part is a 24-hour cycle rotating between 8 hours of regular salt fog (1-2 mL/hr collection) and 16 hours of humidity. This 24-hour part is performed 6 times or 6 cycles to complete testing. After testing is completed, a functional analysis can be performed on the components to determine their durability during testing.

The other test the we take pride in performing at ATC is the GMW 3172 sec. 9.4.8. In this 24-hour test, periods of dry, ambient, and salt spray are used to enhance the corrosion process. The test consists of 1 hour dry at 70 C, 1-hour salt spray at 25 C, and 1 hour at ambient conditions. This process repeats two more times and is then followed by a 15-hour ambient period, completing the 24-hour cycle. However, there are two details that make this assessment distinctive. First, since the components are being sprayed for a total of 3 hours over the course of one cycle, the 5% salt solution is recirculated and cooled in a separate 250 gallon holding tank to avoid having to replenish the solution daily. Typically, the solution is cooled and maintained at 25 C through the entire test. Second, the procedure gives the user the options of having the components powered during testing. For this option, the components would be powered ON during the salt spray and 15-hour ambient steps, while the components are OFF during the dry and 1-hour ambient portions.

GMW 3172

- Quotes within 24 hours

Testing Certificate # 2563.02

Our lab is accredited by A2LA.Scope

A2LA Letter of Accreditation (PDF)

Benefits of ATC Test Lab

A2LA Accredited Test Lab

Many manufacturers want to avoid hiring an accredited professional to conduct their sophisticated testing. By contracting ATC Test Lab you can avoid hiring and training costly specialized employees and equipment to conduct an array of tests.

Our experienced laboratory technicians understand the nature of each test, including GMW 3172. They are able to quickly detect product failure or unusual corrosion.

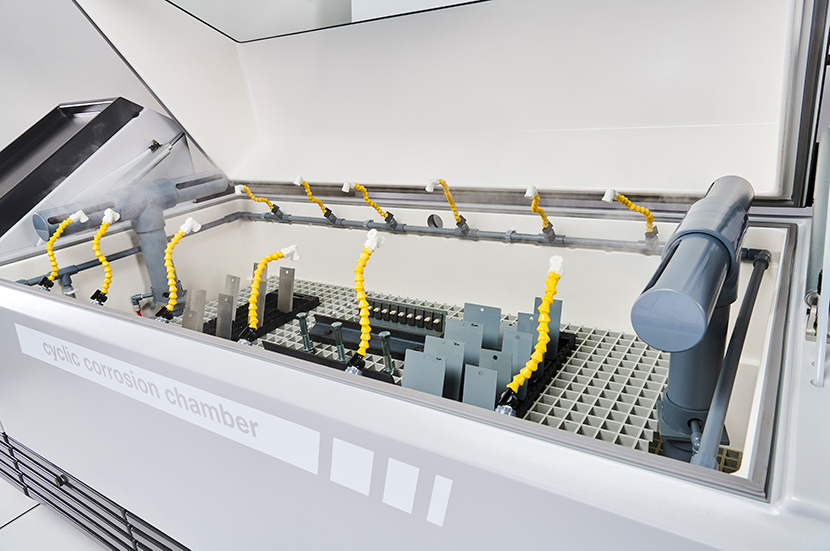

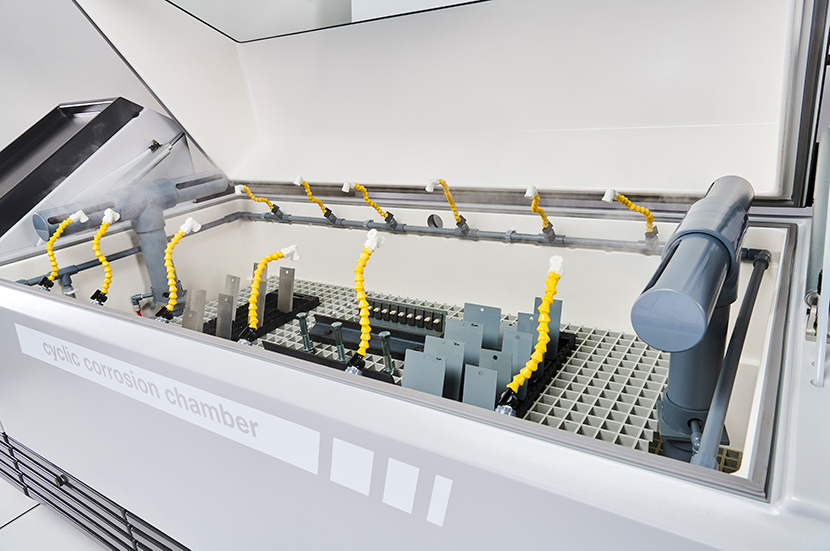

Specialized Testing Equipment and Chambers

ATC has new state of the art equipment to perform the most advanced testing. We have over 1200 Cubic Feet of testing space available, and the largest testing chambers in the world.

By contracting us, you can save money on new costly equipment, maintenance, and down time. You can size and scale your tests based on your level of production.

Receive Photographs and Updates

The best way to monitor your products during the testing process is though digital photography. ATC Test Lab offers high resolution photos at your requested intervals. The use of photographs can help you save money if you need to stop the test early due to product failure or unusual corrosion.

GMW 3172

Cyclic Corrosion

Exposure Testing

ATC Test Lab is the Largest Contract Corrosion Test Lab.

- We have over 1200 cubic feet of testing space available.

- Large testing chambers

- Our lab has state of the art equipment to perform the most advanced testing.

- Experienced laboratory technicians conducting your tests.